Advanced metal surface treatment engineering company in China

Tianjin Jingcheng Weiye Mechanical Manufacturing Co.,Ltd. was established on September 1,2008, which is an advanced metal surface treatment engineering company. This company has two factories in Tianjin, covering an floor area of more than 200 acres, and factory area of more 60,000 square meters with more than 200 sets of large and medium-sized machinery and 4 sets of mandrel, electroplating, hardfacing and welding wire production lines. It also has more than 450 employees and more than 30 patents.

The company follows the principle of "quality first, reputation first", strengths the quality, health, safety and environmental protection managements and has passed the national quality management system, occupational health and safety management system, environmental management system and international certification API 5LD, Q1. its products quality is widely accepted by the market.

60,000+

Factory Area

200+

Production Machinery

450

Employees

30+

Certified Patents

Autumn Inc

Autumn Inc, a wholly-owned subsidiary of Tianjin Jingcheng Weiye Mechanical Manufacturing Co.,Ltd.

Autumn,Inc., located in Houston, Texas,is a company that integrates R&D,production and sales into one concept. Our company supplies new and composite mandrels across the globe through our vast distribution network.We are considered a leader in the renewal of failed mandrels.

Benefits of working with

R&D Team

The number of R&D experiments ranks among the top in China, we have more than 20 patents in the field of anti-corrosive

Detail View →Quality Control

From the perspective of on-site qualitymanagement, manufacturing process quality controlis to strengthen the quality ......

Detail View →Service

We attach great importance to service, because we firmly believe that the timely and efficient service is the best way to win our client’s trust ......

Detail View →

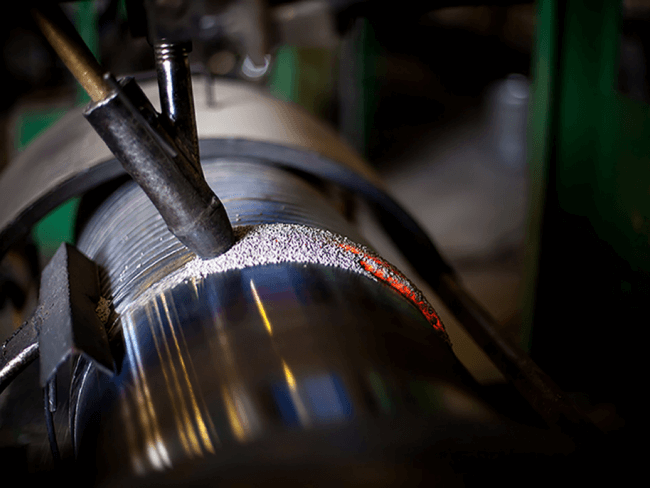

In the field of metal processing

1. Products such as mandrels for processing and repairing seamless steel pipes have accounted for 70% of market segments in China.

2. The produced anti-corrosive and wear-resisting welding wire is widely used in mandrel hardfacing, pipe fittings hardfacing, drill pipe hardfacing and so on.

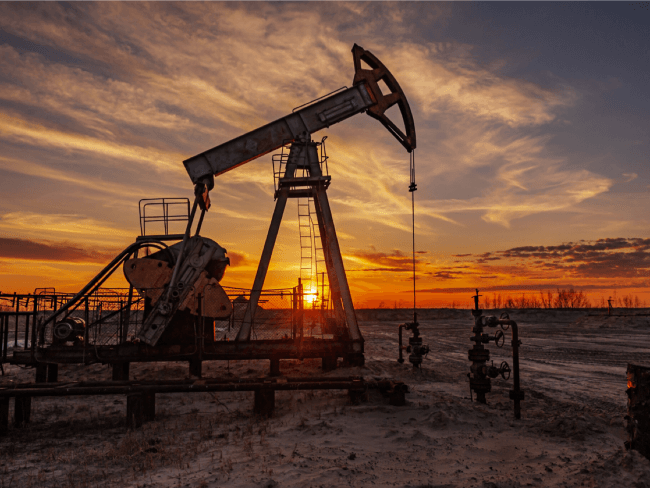

In the field of oil and gas exploration

1. The bimetallic oil tube with hardfacing alloy is to solve the corrosive problem of oil pipeline.

2. The oil tube, bushing and drill pipe produced by electrolytic deposition on the inner and outer walls can solve the corrosive, wearing and wax precipitation and scale formation problems of downhole tools.

In the field of anti-corrosion and wear-resistance

1.The valves, elbows and tees repaired by alloy hardfacing have solved the corrosive and wearing problems of process pipeline.

2.The produced bimetallic composite oil tube and pipe fittings have effectively solved the corrosive problem of offshore and onshore oil transportation.

3.The applied special electrolytic deposition have solved the problem of uniform coating thickness on curved workpieces such as screw rotors, reduced the coating porosity and prolonged the service time of the product.